Coprocessing in Plastic Circularity: A Technology Perspective (Part B)

Introduction

Plastic Pyrolysis Oil (PPO) is a valuable product created from the thermal breakdown of waste plastics. It typically has a high energy content and can be refined into fuels and chemicals. However, refineries face challenges in effectively utilizing this resource to enhance plastic recycling efforts. PPO consists of a complex mix of hydrocarbons, including alkanes, alkenes, aromatics, and oxygenated compounds. Its quality can change based on the type of plastic used and the conditions during pyrolysis, which can affect refinery operations and the quality of the end products. To meet refinery standards, PPO often needs upgrading through methods like hydrotreating, hydrocracking, and catalytic reforming. Refineries may also need to adjust their systems and processes to handle PPO. The economic viability of incorporating PPO into an existing refinery configuration will depend on its cost, refinery’s configuration, the value of the resulting products, and the expenses related to upgrading and processing.

This whitepaper examines the advantages and challenges of adding PPO to refineries, offering a detailed look at PPO’s composition, its potential effects on the refining sector, and the key factors for successful integration. The focus is on the characteristics of raw PPO, assuming it is available in small amounts from various sources. Since it is not cost-effective to hydrotreat small quantities of PPO, the paper also points out possible locations within refineries, depending on their setup, where PPO could be introduced alongside traditional feedstocks.

Understanding the plastic pyrolysis oil properties

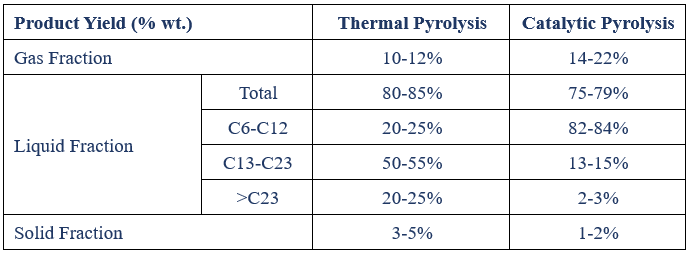

The properties of plastic pyrolysis oil can vary based on the type of waste plastic feed and how the pyrolysis process is carried out. In catalytic pyrolysis, there is usually more gas produced, and less liquid hydrocarbon compared to thermal pyrolysis. For raw plastic pyrolysis oil, it’s important to look at the amount of liquid hydrocarbons produced. The naphtha cut is particularly significant; in catalytic pyrolysis, most of the liquid hydrocarbons end up as naphtha, while in thermal pyrolysis, the output is divided into light, medium, and heavy cuts. A comparison of these processes is shown in Table 1.0 .

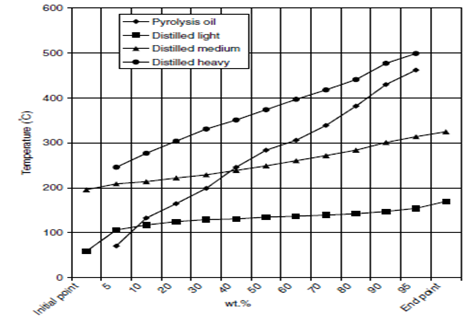

In catalytic pyrolysis, a catalyst helps speed up the cracking reaction by reducing the temperature and time needed. This process creates hydrocarbon liquids with shorter chains that fall within the gasoline range and have a high-octane number. In contrast, thermal pyrolysis produces heavier oils with a lower octane number. Catalytic pyrolysis effectively eliminates most impurities during the process, while the hydrocarbon liquids from thermal pyrolysis contain more impurities that must be cleaned up later through hydrotreatment. Figure 1.0 below illustrates a standard TBP curve analysis of raw PPO obtained from a thermal pyrolysis process.

For refinery integration, the focus is on the liquid hydrocarbon stream. It’s crucial to know the makeup of plastic pyrolysis oil to determine where it can be integrated with traditional feedstock in the refinery. Key properties to examine include:

- PIONA (paraffins, iso-paraffins, olefins, naphthenic, and aromatics) levels

- TBP curve (temperature range and cuts)

- cNitrogen and Chloride levels

- Stability (gum formation) and diene levels

- Halogen levels

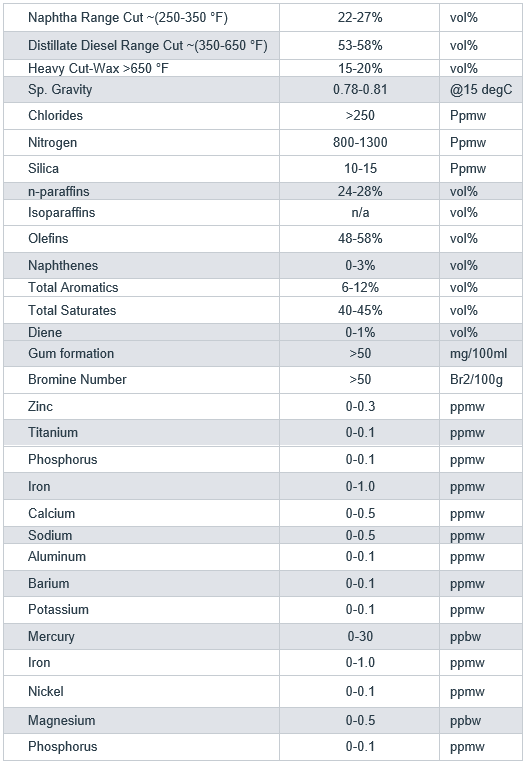

Assuming that the objective of the pyrolysis process is attaining plastic circularity, its operating conditions are maintained accordingly and a waste plastic feedstock enriched in polyolefins (PE+PP in the range of ~65-70%) is the key towards higher yield of plastic pyrolysis oil from the process.The table 2.0 below presents the typical composition ranges of plastic pyrolysis oil from such a thermal pyrolysis process.

Plastic waste from various sources contains harmful substances that appear in pyrolysis products. When volatile chlorine and sulfur are present in the feedstock, they create HCl and H2S in both the gas and liquid outputs. Most of the heteroatoms are found in the gas phase, while metals accumulate in solid carbon products. The contaminants (O, Cl, Fe, Na, Si) are known to cause issues such as corrosion, clogging and downstream catalytic poisoning.

A study by Kusenberg et al. highlighted the need to clean pyrolysis products before steam cracking. The researchers examined the steam cracking of PPO mixed with fossil naphtha and compared the results to pure naphtha. The PPO/naphtha mixture produced about 23% ethylene at 820 °C and around 28% at 850 °C, which was better than pure naphtha’s yields of approximately 22% and 27% at those temperatures. However, the PPO/naphtha blend led to significant coke formation and fouling in heat exchangers, which was linked to the heteroatoms and metal contaminants in the plastic waste. The raw plastic pyrolysis oil (PPO) has a high level of olefins, chlorides, and yields in the diesel range, but it is also unstable. These characteristics will require special handling and integration with standard refinery feedstocks. The high olefin content in PPO is similar to traditional coker naphtha, which needs specific processing to saturate diolefins and olefins, as well as to remove sulfur and nitrogen to avoid equipment issues. The distillate cut range indicates that the PPO mainly consists of diesel-range hydrocarbons, so it is important to compare its refining value to the price of paraffinic naphtha. Chloride levels pose a significant challenge, as they must be kept below 1 ppmw in the refining process to reduce the risk of corrosion from hydrochloric acid. Additionally, transportation may be problematic due to the potential for gum formation during transit, given the instability of PPO.

It is important to note that the type of waste plastic used in pyrolysis greatly affects the yields and TBP curves. For the pyrolyser, if we use mechanically recycled post-consumer resin (PCR) made only from polyolefins, the resulting pyrolysis oil will have a notable increase in heavy cuts, such as wax.

Insertion points in refineries

There are some similarities between the PPO stream and the coker naphtha stream in refineries. Both Delayed Cokers and Fluid Catalytic Cracking (FCC) units create olefinic naphtha streams. However, coker naphtha is harder to process because it has a high di-olefin content, contamination from silicon/silica due to anti-foam chemicals in coke drums, and higher nitrogen levels. In contrast, crude oil naphtha lacks olefins and has very low nitrogen. Downstream naphtha processing equipment, like isomerization and reforming, typically requires a maximum of 0.5 – 1 ppmw of nitrogen. Coker naphtha can be treated in specialized hydrotreaters designed to remove diolefins, olefins, silicon/silica, and nitrogen, or in other units that recover naphtha, such as Vacuum Gas Oil (VGO) hydrotreaters or hydrocrackers.

Here are some potential points in refineries for the raw PPO insertion based on its composition:

- Crude Desalter Unit: Chloride mainly comes from crude oils and the chloride added to Catalytic Reforming Units and Isomerization Units to improve catalyst performance. One way to reduce the high chloride levels in raw PPO is to mix it with the crude oil desalter in the refinery. A single-stage desalter can remove about 90% of chlorides, while a two-stage desalter can achieve up to 99%. However, high nitrogen levels in raw PPO can create issues. Nitrogen compounds act as bases and can hold onto chlorides, leading to gas oils that are also high in nitrogen and chlorides. This situation can harm the operation of hydroprocessing and FCC units. The main problems caused by chlorides include stress corrosion cracking in pipes and vessels, which increases risks and costs, and fouling in heat exchangers due to salts from inorganic chlorides. Fouling can reduce unit efficiency and hurt profits. Refineries manage chlorides using crude unit desalters and chloride absorbents to clean chlorides from the hydrogen in Catalytic Reformers. If raw PPO is processed in a crude unit, the refinery needs to hydrotreat both light and heavy naphtha and ensure the crude naphtha hydrotreater can effectively remove dienes, silicon, and nitrogen. Refineries with coker units are more likely to have this capability, but it requires specific knowledge of the refinery’s naphtha processing setup.

-

Click to expand image © 2025 OPIS, LLC Delayed Coker Unit: Raw PPO is similar to coker naphtha, making it a good choice for refineries. However, it’s important to remove the chlorides first. Next, we need to consider the available capacity of cokers. It’s also crucial to think about how much mixing will occur, as this should not affect downstream operations.

- Hydrocrackers: This point insertion can handle most of the basic PPO qualities in small amounts, except for the chloride content. Therefore, PPO fed to a hydrocracker needs to have a pretreatment to remove basic chloride and possible halogens.

- Fluid Catalytic Cracker Unit: Refineries that have FCC can best utilize the raw PPO stream, but they need to control chlorides to below 3 ppm in the feed. Chlorides must be either removed or mixed with other feeds to reach a total of 3 ppm. FCC units already create olefinic naphtha and distillate. The cracking of polyolefinic pyrolysis waxes in an FCC unit has been studied extensively. Studies have shown that the cracking of waxes leads to higher yields of gasoline compared to the cracking of VGO.

- Reformer: The Liquid wax derived from the pyrolysis of waste plastic can be fed, along with oil products, into steam reforming, hydroprocessing, FCC and coking processes for fuel production.

Major challenges and possible solutions

Diene and chloride levels in raw PPO are significant challenges because they restrict its use in refineries. To improve quality before sending raw PPO to refineries, removing chlorides is a key step. This action can expand the customer base, allowing raw PPO to be processed in any FCC unit or hydrocracker without worries about chloride corrosion, thus increasing its market value.

Additionally, removing dienes addresses transport and storage issues related to gum formation. The risk of gum formation in raw PPO is significant, so it’s best to have refining partners nearby to minimize the chance of gumming during transport. Reducing nitrogen in the naphtha cut and lowering silicon content would enable the raw PPO to be processed in any crude unit, not just those with cokers and naphtha hydrotreaters designed for coker naphtha and crude naphtha. It is also important to monitor the refinery configuration and its distance from the raw PPO unit, as not all refineries have the same setup. Each refinery must assess how much raw PPO can be integrated into their existing systems without operational difficulties.

Conclusion

Adding PPO to refineries is a hopeful approach to tackle the rising issue of plastic waste and support a sustainable future. As technology improves and the need for eco-friendly fuels and chemicals rises, PPO’s importance in the refining sector is expected to increase.

Assessing the economics of processing PPO in an existing refinery is a challenging exercise that requires considering the operating economics of the overall refining complex This requires detailed economic evaluations to determine the cost-effectiveness of this method . The economic viability of utilizing pyrolysis oil in refineries for fuel purposes presents a distinct scenario. However, the feasibility of processing plastic pyrolysis oil in refineries, aimed at enhancing plastic circularity, is influenced by various factors. These include production scale, market demand for by-products, incentives for claiming recycled content, technical process control parameters, and emissions considerations. While large-scale operations may benefit from reduced per-unit production costs, they necessitate substantial initial investments. Therefore, scale is a critical factor, and it is essential to assess the extent to which pyrolysis oil can be blended without adversely impacting downstream processes. Additionally, the establishment of markets for by-products such as biochar or light fuel fractions can generate supplementary revenue streams. Government policy support is also crucial in providing incentives and premiums for higher recycled content claims. Furthermore, variations in feedstock composition, inadequate process controls, and inconsistent management practices can result in emissions exceeding expectations, which must be taken into account.

To unlock PPO’s full potential, ongoing research and development are essential to enhance its quality and reliability, refine upgrading methods, and create new technologies for its use in refineries. By overcoming challenges and seizing opportunities, the refining industry can significantly contribute to a circular economy for plastics.

Jonny Goyal

Director, Circular Plastics Service

Chemical Market Analytics by OPIS, a Dow Jones Company